cnc turning service vs. manual turning: which should you choose?

How CNC Machining Services Improve Performance in Milling and Turning Processes

CNC machining solutions play a pivotal duty in improving efficiency within milling and transforming procedures. By making use of automation and accurate control, these services reduce human mistake and assurance constant outcome. The ability to deal with complicated geometries and preserve limited tolerances streamlines manufacturing. Nevertheless, the full degree of CNC technology's effect surpasses fundamental efficiency gains. There are much deeper implications and future trends that call for additional expedition.

The Essentials of CNC Machining

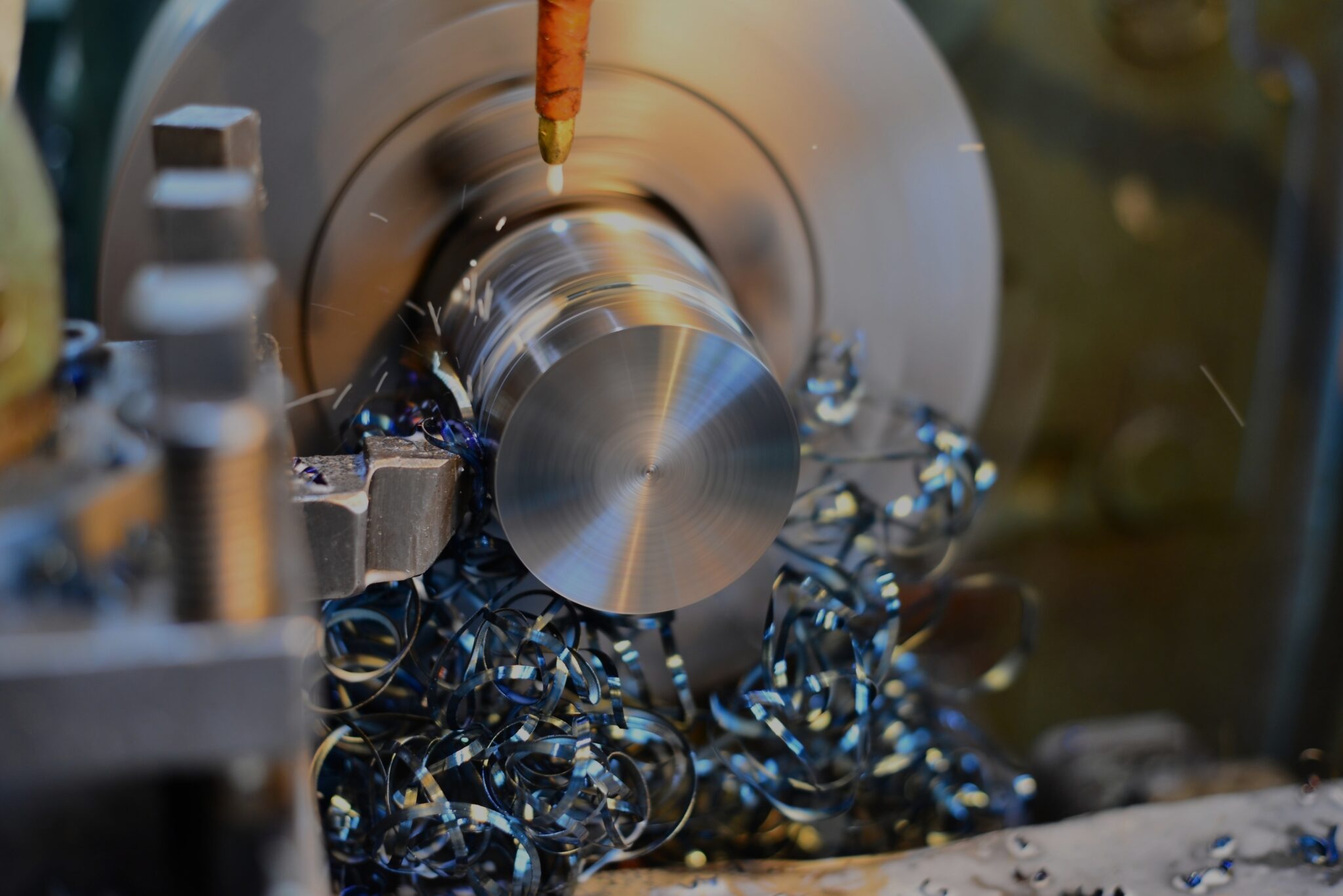

CNC machining is an accurate manufacturing process that utilizes computer-controlled devices to generate detailed components and elements. This technology uses computer-aided design (CAD) software application to produce thorough models, which are after that converted right into machine guidelines. The process normally entails numerous operations such as milling, turning, and drilling, allowing manufacturers to accomplish high levels of precision and repeatability.

CNC devices are geared up with innovative tooling that can adjust products like plastic, wood, and metal. They operate via a series of commands that determine movements, rates, and device adjustments, decreasing human error and improving production effectiveness.

The automation inherent in CNC machining permits complex geometries and limited tolerances to be regularly produced, making it a favored choice in industries requiring accuracy, such as aerospace and vehicle. Recognizing the principles of CNC machining is important for valuing its function in contemporary manufacturing processes.

Advantages of CNC Machining in Milling

CNC machining offers considerable benefits in milling procedures, specifically concerning precision and precision. This technology not only improves production rate however additionally enables the production of complicated styles that would certainly be testing to achieve manually. Therefore, organizations can improve effectiveness and expand their abilities in manufacturing.

Precision and Accuracy

Accomplishing exceptional accuracy and precision in milling procedures is a hallmark of advanced machining strategies. CNC machining services utilize computer-controlled systems that thoroughly perform styles with marginal human intervention. This automation guarantees that each cut and shape is executed to exact specs, substantially lowering the risk of mistakes normally related to hand-operated milling. The capability to produce intricate geometries with tight tolerances is a key benefit, permitting suppliers to fulfill stringent top quality needs. In addition, CNC equipments can keep regular efficiency throughout several runs, ensuring uniformity in production. This level of accuracy not just boosts item high quality however likewise decreases material waste, leading to extra reliable usage of resources. In general, CNC machining services change milling procedures with their commitment to accuracy and information.

Boosted Production Speed

Accelerating production rate is just one of the standout advantages of contemporary machining solutions. CNC machining considerably minimizes the time needed for grating procedures by automating operations and reducing manual treatment. Equipments can run constantly, allowing for boosted outcome without sacrificing top quality. The capability to program multiple jobs into a solitary configuration better improves production, allowing suppliers to total facility tasks in less time. Additionally, CNC equipments maintain high-speed reducing capacities, leading to quicker product elimination and faster cycle times. This enhanced performance translates to shorter preparations, enabling companies to respond promptly to market needs. In general, boosted manufacturing speed through CNC machining not just increases performance yet additionally enhances competitive advantage in the production field.

Facility Style Capacities

The ability to develop detailed layouts is a considerable advantage of modern machining services. CNC machining enables the manufacturing of complex geometries that would certainly be challenging, if not impossible, to achieve utilizing standard techniques. This ability originates from sophisticated programs and automated tools that precisely comply with electronic blueprints, making sure accuracy and repeatability. Consequently, manufacturers can produce intricate get rid of limited resistances, maximizing performance in numerous applications. Additionally, the flexibility of CNC machines makes it possible for fast modifications to create specs without substantial retooling, streamlining the production process. This versatility not only enhances imagination in style however likewise enables effective testing and technology, giving businesses an affordable side in the ever-evolving market.

Benefits of CNC Turning Procedures

CNC turning procedures use substantial benefits in production, especially pertaining to precision and accuracy. These procedures permit the production of very detailed elements with very little resistances, guaranteeing quality in production. Furthermore, the performance of CNC transforming contributes to minimized lead times, allowing faster distribution of ended up items.

Precision and Accuracy

Precision and accuracy are characteristic attributes of CNC turning processes, establishing them apart in the production landscape. These procedures use computer system numerical control to direct reducing tools with unmatched exactness. This causes parts that fulfill strict specifications and tolerances, decreasing the probability of errors. CNC turning enables repeatable and consistent production, ensuring that each component is basically similar, which is important in markets calling for high requirements, such as aerospace and clinical tools - jig Discover More Here and fixture tooling. Additionally, progressed software application and modern technology allow real-time adjustments during machining, boosting overall quality. By reducing human error and taking full advantage of control over the production procedure, CNC transforming solutions deliver exceptional precision and precision, making them an essential option for contemporary production requirements

Decreased Lead Times

Decreased lead times are a substantial benefit of CNC turning procedures, stemming from their capability to enhance and automate manufacturing. CNC turning makers run with high effectiveness, permitting fast arrangement and execution of multiple tasks without the demand for extensive hands-on intervention. This automation minimizes downtime and accelerates the production procedure, making it possible for quicker turn-around for orders. Furthermore, CNC modern technology improves consistency and decreases mistakes, which better contributes to quicker manufacturing cycles. Therefore, businesses can satisfy tight target dates and react without delay to market needs. By leveraging CNC transforming procedures, companies can streamline process, improve resource allocation, and eventually boost their one-upmanship through reduced preparations.

Precision and Accuracy in Production

While producing procedures have advanced substantially throughout the years, the relevance of precision and precision stays extremely important. In CNC machining, these 2 elements are essential to creating high-quality components that fulfill specific specs. The assimilation of sophisticated computer modern technology permits for precise control over machining specifications, making sure that components are crafted with marginal discrepancy from desired layouts.

Precision in making refers to the repeatability of processes, while precision denotes how carefully a finished part aligns with its intended dimensions. CNC equipments make use of innovative software program and devices that make it possible for manufacturers to accomplish both, noticeably lowering the margin for mistake - cnc milling services near me. This ability is especially necessary in markets such as aerospace, automotive, and medical, where also small errors can result in disastrous failures

Decreasing Lead Times With CNC Modern Technology

CNC modern technology accelerates production timelines by streamlining the machining procedure. By automating jobs, CNC equipments minimize hand-operated treatment, greatly decreasing the time needed for setup and operation. This efficiency makes it possible for makers to respond swiftly to market needs, fulfilling orders quicker than traditional machining approaches permit.

Furthermore, CNC modern technology supplies fast prototyping capabilities, permitting for quick versions and modifications based upon customer responses. The precision of CNC machining guarantees that components are generated properly the very first time, reducing the likelihood of expensive mistakes and rework.

Moreover, advanced organizing and programming capacities enhance workflow, enabling numerous procedures to run simultaneously. This assimilation of technology not only reduces lead times but also enhances overall efficiency. Ultimately, the adoption of CNC machining solutions furnishes makers with the tools required to meet limited deadlines while preserving high-grade criteria see here in manufacturing.

The Future of CNC Machining in Sector

As makers progressively embrace CNC innovation to enhance procedures and minimize lead times, the future of CNC machining in sector appears promising. Advancements such as expert system and artificial intelligence are established to transform the capacities of CNC machines, improving their accuracy and adaptability. These innovations will assist in real-time surveillance and anticipating maintenance, minimizing downtime and optimizing production efficiency.

In addition, the integration of Web of Points (IoT) innovations will certainly enable much better data collection and analysis, enabling makers to make educated decisions that better boost operational efficiency. The increase of additive production alongside CNC machining is anticipated to match conventional methods, giving greater design flexibility and product effectiveness.

Additionally, as sustainability comes to be a concern, CNC machining is advancing to include environment-friendly practices, which will certainly attract environmentally mindful customers. Overall, the future of CNC machining is characterized by continual technology and adjustment, positioning it as a keystone of modern production.

Regularly Asked Inquiries

What Products Are Compatible With CNC Machining Services?

CNC machining services work with numerous products, including steels like light weight aluminum, steel, and titanium, as well as plastics such as acrylic and polycarbonate. Timber and composites additionally suit CNC processes for diverse applications.

Just How Does CNC Machining Compare to Traditional Machining Methods?

CNC machining provides greater automation, accuracy, and uniformity compared to traditional methods. It minimizes human mistake, enhances manufacturing rate, and allows for complicated styles, making it a remarkable choice in modern manufacturing environments.

What Industries Benefit one of the most From CNC Machining Providers?

The aerospace, automobile, clinical, and electronic devices industries profit significantly from CNC machining solutions. These fields utilize precision, speed, and personalization to improve product top quality while decreasing production costs and time, ultimately enhancing overall functional efficiency.

Can CNC Machines Handle Complex Geometries and Styles?

CNC makers are skilled at taking care of intricate see this website geometries and layouts, enabling for precision and complex detailing. Their advanced programs capacities make it possible for producers to produce elements with high accuracy, conference varied sector needs and improving item performance.

What Is the Typical Expense Array for CNC Machining Services?

The common price variety for CNC machining services varies widely, normally dropping in between $50 to $150 per hour, depending upon variables such as material, intricacy, quantity, and the details machining procedures used.

CNC machining is an exact manufacturing procedure that makes use of computer-controlled equipments to produce detailed components and components. CNC machining provides considerable advantages in milling procedures, specifically pertaining to precision and precision. CNC machining substantially minimizes the time needed for grating processes by automating procedures and lessening manual treatment. CNC modern technology speeds up manufacturing timelines by improving the machining process. As suppliers increasingly adopt CNC modern technology to simplify procedures and lower lead times, the future of CNC machining in industry shows up encouraging.